While the opening size has huge ramifications when it comes to product quality, the selection of nozzle material has to do more with its compatibility with World of Warcraft 3D printing models Mortal Kombat STL files Witcher STL files Joker STL files MechWarrior Online models to craft on a 3D printer Other popular STL files to craft It takes up to 30 minutes to change a nozzle on a 3D printer from 0. Cool the hot end while maintaining steady filament strand pressure.

Hercules™ nozzles are the clear cut choice for printing with more abrasive filaments like our CarbonX™ Carbon Fiber grades.

4mm-240℃ High Speed Nozzle The printer acts generally the same as a traditional inkjet printer in the direct 3D printing process, where a nozzle moves back and forth while dispensing a wax or plastic-like polymer layer-by-layer, waiting for that layer to dry, then adding the next level. One way to check if your nozzle is bad is to do a straight extrusion test.

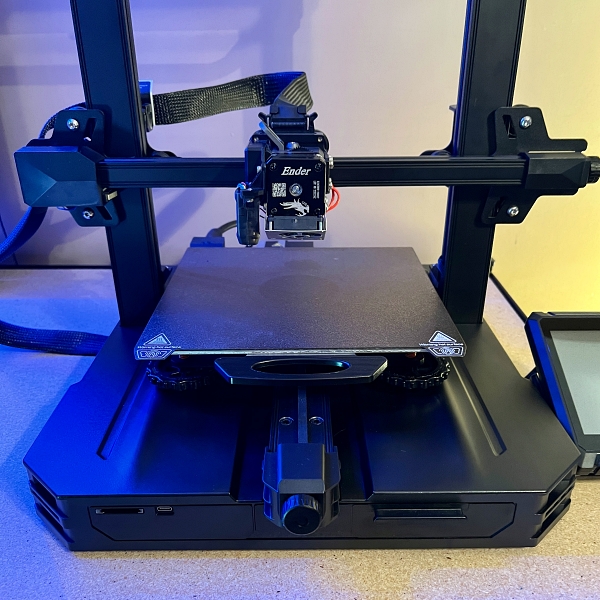

Leave the nozzle in the solvent for 24 hours, agitating it every few hours. 75 mm 3D Printer MK8 Nozzles Tool High Temperature Wear Resistant Compatible with Makerbot, Creality CR-10 All Metal Hotend, Ender 3/ Ender3 pro, Prusa i3 (5 Pieces) and find millions of items, delivered faster than ever. This should leave the shape of the inside of your nozzle on the end of the filament. It’s also important to deep clean your nozzle from time to time to keep it in its best printing condition and prolong its lifespan.

E3d revo ender 3 v2 how to#

Cleaning it properly is important! Learn how to clean your 3D printer nozzle. 00:00 - In Retraction – Slower retraction speed compared to a smaller nozzle, but highly dependent on the situation. Heat the nozzle to the printing temperature ( about 230☌ ). Below, we have listed the most common reasons that can cause 3D printer filament to clump on the nozzle: The distance between the nozzle and the build plate is too great. If your nozzle is in good condition, you should see a squirt of plastic straight down. If you purchase using a shopping link, we may earn a commission. To keep things this way, we finance it through advertising and shopping links. which calibrates the difference in height between the nozzle and bed. Developed for use while printing extremely abrasive Boron Carbide filament, the Olsson Ruby prints kilograms of even the most abrasive consumer filaments with no visible signs of wear. The general consensus for nozzle diameter versus layer height is to limit the layer thickness to eighty percent of the nozzle diameter. The first thing you should do is to inspect your filament before loading it into your 3D printer. To quickly recap, here are the things that can cause PETG to stick to the nozzle: The print temperature is too low. Swapping your 3D printer's nozzle is one of the easiest upgrades that can be done. Three prints in total to get this effect. One of the best ways to remove a stuck nozzle on your 3D printer is to heat the nozzle up to at least 245☌ then use a ratchet to undo it. To … How to remove a broken nozzle from a hotend on your 3D printer. the Olsson Precision Nozzle Home of The Olsson Ruby.

0 kommentar(er)

0 kommentar(er)